Incorporating high speed, closed loop axis control within the PC allows a highly cost-effective CMM solution. On-board signal conditioning circuitry ensures high-precision position measurement so that external probe conditioning equipment is no longer needed.

An ActiveX control encapsulates the functionality required by CNC CMM applications in a fast, easy to use component that is compatible with rapid application development tools such as Visual Basic and Visual 'C'. Example source code demonstrates the capabilities of the ActiveX, which is also compatible with many popular 3rd-party CMM software packages. Axis tuning and jogging facilities are provided for easy machine set-up.

Plug 'n' Play software support for 32 bit and 64 bit versions of Windows XP/Vista/Win 7/8/10 enables simple installation and automatic configuration of up to 4 controllers supporting a total of 16 axes.

Features

- 4/8 axes of servo control

- 2 axes of open or closed loop stepper control

- 2 encoder channels

- Zoom lens power

- High performance:cost ratio

- Linear, civular, helical & sperical interpolation

- 16/12 opto-isolated digital inputs & outputs

- Fully featured integrated prove cycles

- Comprehensive axis and move status monitoring

- Joystick probe protection mode

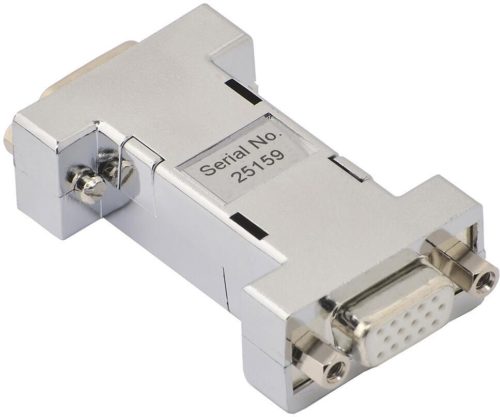

- Renishaw PICS A and PICS B connections

- Comprehensive user manual

- Support & demonstration software on USB